Business Management creates factories using classroom concepts

November 9, 2015

A break from their normal computer generated simulations, Glenda Eichman’s Business Management students designed their own real-life simulation when they created an assembly line to produce paper airplanes.

After studying management within a production system, students designed their own facilities complete with plane and logo designers, plane producers, quality inspectors and inventory and production managers.

“They were put into two groups and within those groups,” Eichman said, “they had to figure out who would get what position. They had to talk about their strengths and weaknesses.”

After a day of planning on Thursday, Eichman tasked each group to use their chosen production system to create a minimum of 10 paper planes in 10 minutes while maintaining quality.

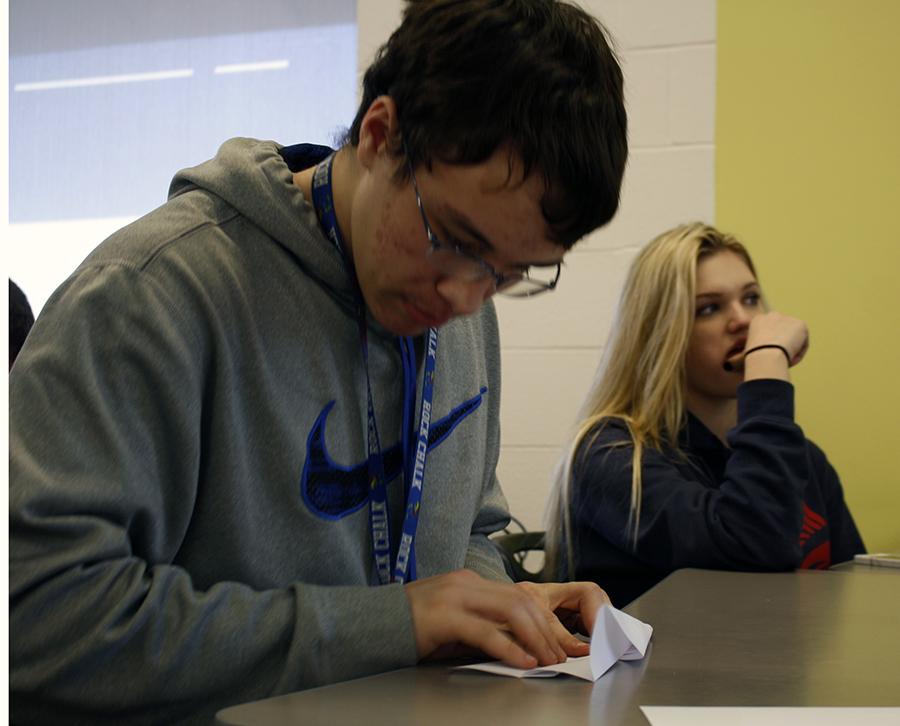

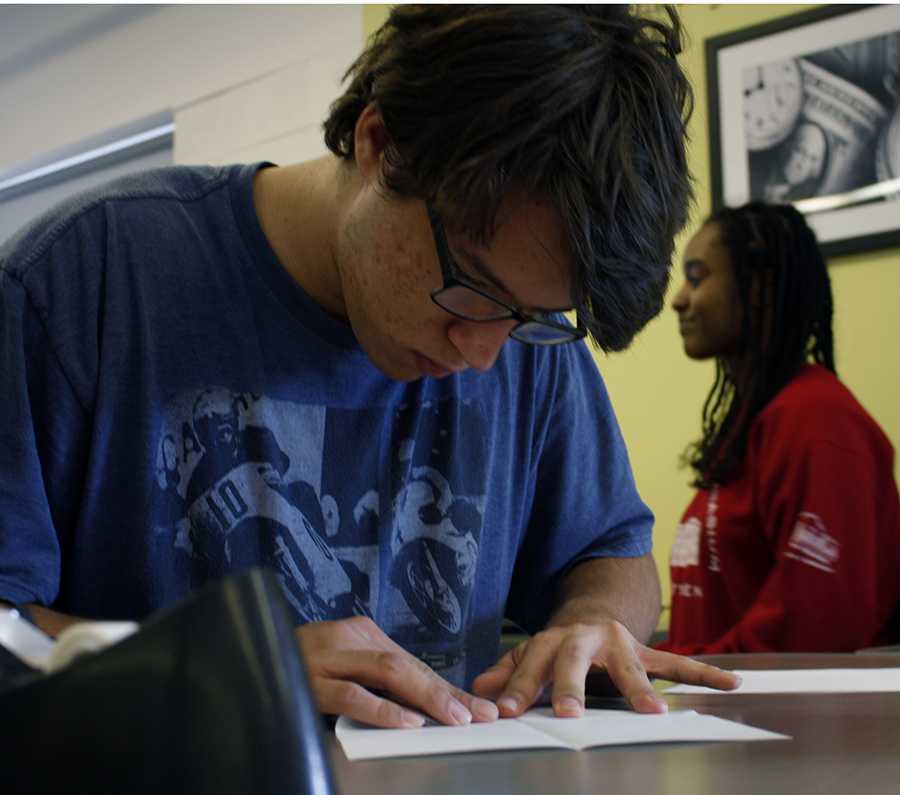

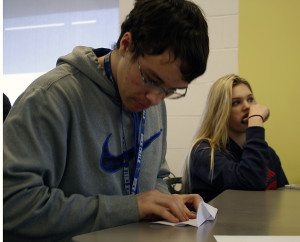

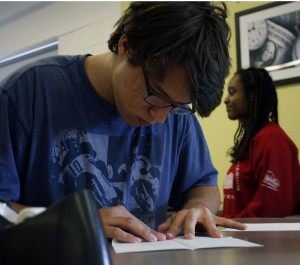

As the activity began, inventory managers rushed into the hall where they gathered their facility’s supplies. After distributing paper, the producers quickly began precisely folding the planes in the style decided by designers the day before.

“I had to focus on where I was folding,” Manhattan Mobsters plane producer Josh Morse said. “It got harder as I went on and my hands got tired.”

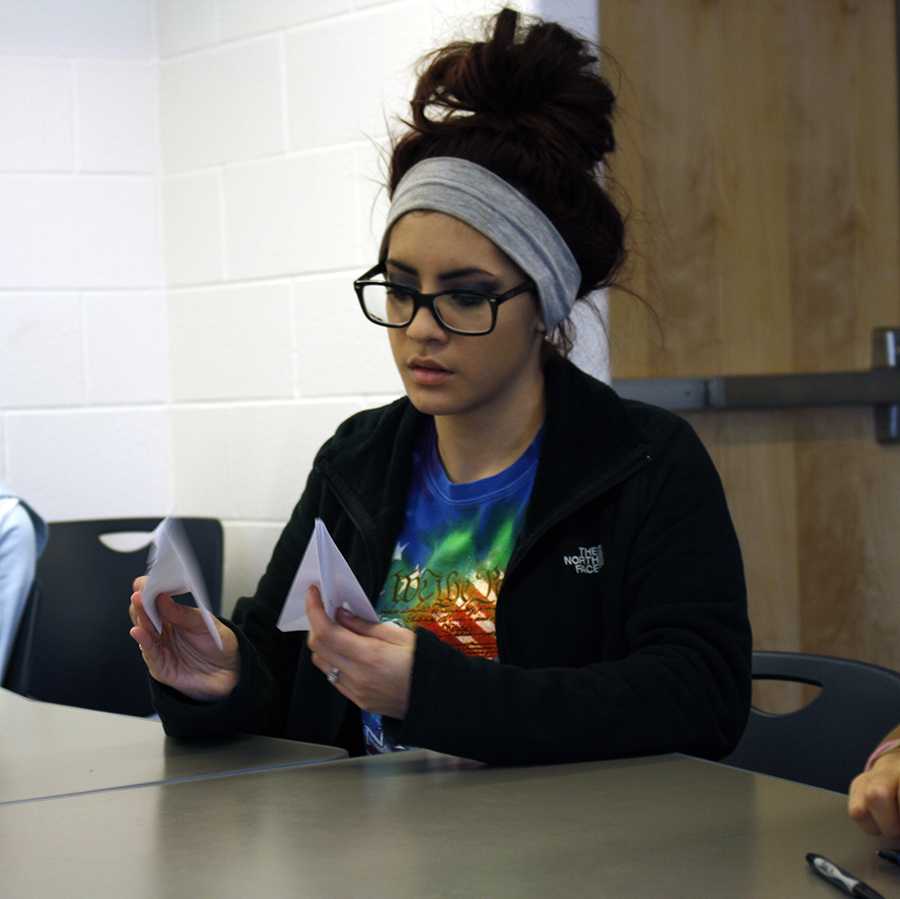

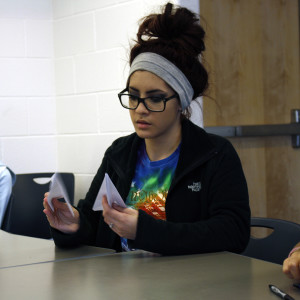

Next, planes were passed to the logo designers where a design representing their company’s name was drawn. At the end of the line, an inspector compared each plane to a prototype, looking for consistency in folding and logo design. All the while, a production manager watched over the “factory” and provided assistance when needed.

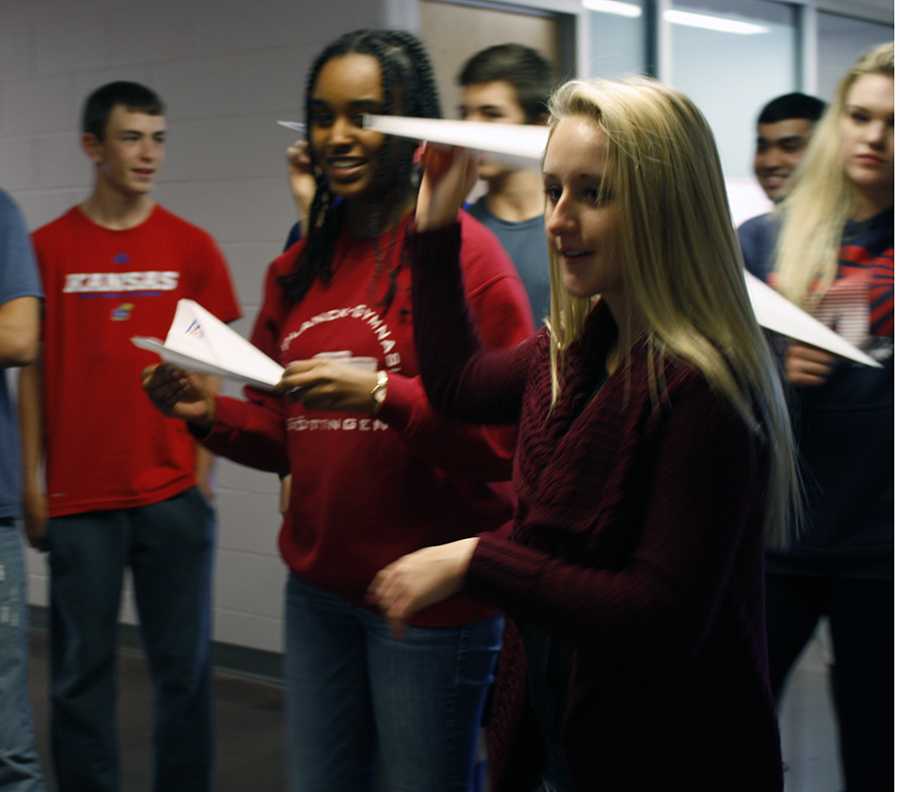

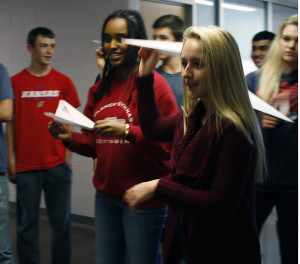

Once time was up, planes left on the line were counted as wasted product and the workers gathered in the hall where the best two planes from each group were flight tested. The group with the farthest flying plane received extra points.

“We won, so I thought our plane flyed well,” Paper Plane Company plane designer Trever Dillon said. “There wasn’t really anything that didn’t go well except, I guess, we left one plane on the assembly line.”

Though the main purpose of the simulation was to gain a better understanding of terms and concepts studied, students came away with more.

“I think it shows you maybe how stressful an actual production job can be in a factory,” Morse said. “I think I’d be more sympathetic to people who are working because now, I kind of know what they go through, the stress that they deal with.”

The real life simulation proved a success as students applied the concepts learned in class.

“It’s fun,” Eichman said. “I just think it’s one of those where they like learning it in that way versus just talking about it, but actually doing it. [It’s] good for a Friday too.”